Grn methanol

From the Power of the sun!

Grn methanol

From the Power of the sun!

The TUNol project

TUNol is a project of the SUNol consortium in Tunisia and aims to use the solar energy of the Sahara to produce the sought-after raw material methanol. In order to convert the solar energy into electricity, the TUNol project will build an Integrated CSP-PV Hybrid Power Plant (ICPH) at a selected site, which will generate renewable electricity and heat day and night. The generated electricity from the CSP-PV hybrid power plant will then be fed to an electrolysis process to split demineralized water into the chemical elements; hydrogen (H2) and oxygen (O2). In addition, aCO2 capture plant will be constructed. This will be used to recover pureCO2 instead of emitting it into the atmosphere. From the carbon dioxide (CO2) and hydrogen (H2) produced in this way, green methanol is synthesized in a catalytic process and then concentrated to produce methanol with a purity of 99.85%. Green methanol can be used as a base chemical, synthetic fuel and for many other industrial purposes. In this respect, the project also provides an important source of revenue for Tunisia in an attractive future market.

The TUNol project

TUNol is a project of the SUNol consortium in Tunisia and aims to use the solar energy of the Sahara to produce the sought-after raw material methanol. In order to convert the solar energy into electricity, the TUNol project will build an Integrated CSP-PV Hybrid Power Plant (ICPH) at a selected site, which will generate renewable electricity and heat day and night. The generated electricity from the CSP-PV hybrid power plant will then be fed to an electrolysis process to split demineralized water into the chemical elements; hydrogen (H2) and oxygen (O2). In addition, aCO2 capture plant will be constructed. This will be used to recover pureCO2 instead of emitting it into the atmosphere. From the carbon dioxide (CO2) and hydrogen (H2) produced in this way, green methanol is synthesized in a catalytic process and then concentrated to produce methanol with a purity of 99.85%. Green methanol can be used as a base chemical , synthetic fuel and for many other industrial purposes. In this respect, the project also provides an important source of revenue for Tunisia in an attractive future market.

Key figures

MEGAWATT

Power

KILOTONS/YEAR

Carbon dioxide saving

GWh/YEAR

Heat potential

KILOTONS/ YEAR

Methanol

KILOTONS/ YEAR

Oxygen

Key figures

MEGAWATT

Power

KILOTONS/YEAR

Carbon dioxide saving

GWh/YEAR

Heat potential

KILOTONS/ YEAR

Oxygen

KILOTONS/ YEAR

Methanol

SUNol Consortium

The Sun-OL consortium consists of the following industry and research partners:

(associated)

(associated)

(associated)

(associated)

The Tun-OL project is additionally funded by the German Federal Ministry for Economic Affairs and Climate Protection

FKZ: 03EE5123C

The TUol project is additionally supported by the

Federal Ministry for Economic Affairs and Climate Protection funded

FKZ: 03EE5123C

Motives and goals

- Growing pressure for decarbonization due to climate change and 2-degree target

Demand for CO2-free solutions

- Strongly increasing demand for green H2 / derivatives currently and in the future

Demand for production capacities - Implementation of multinational H2-Strategies for the transformation of the energy infrastructure

Creation of the framework for the development of a new industrial sector

=> Construction of an integrated production plant for the large-scale production of green methanol in Tunisia

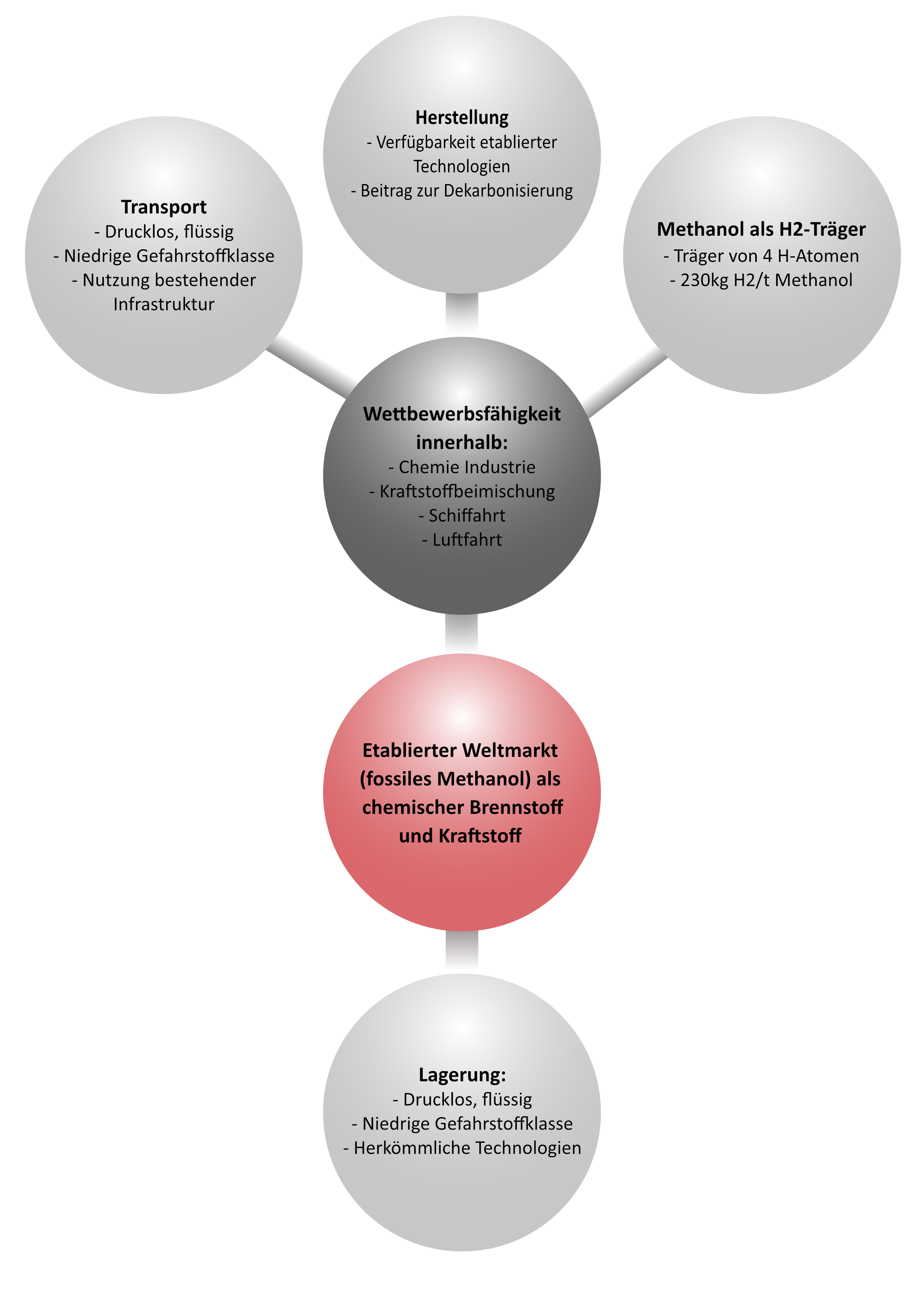

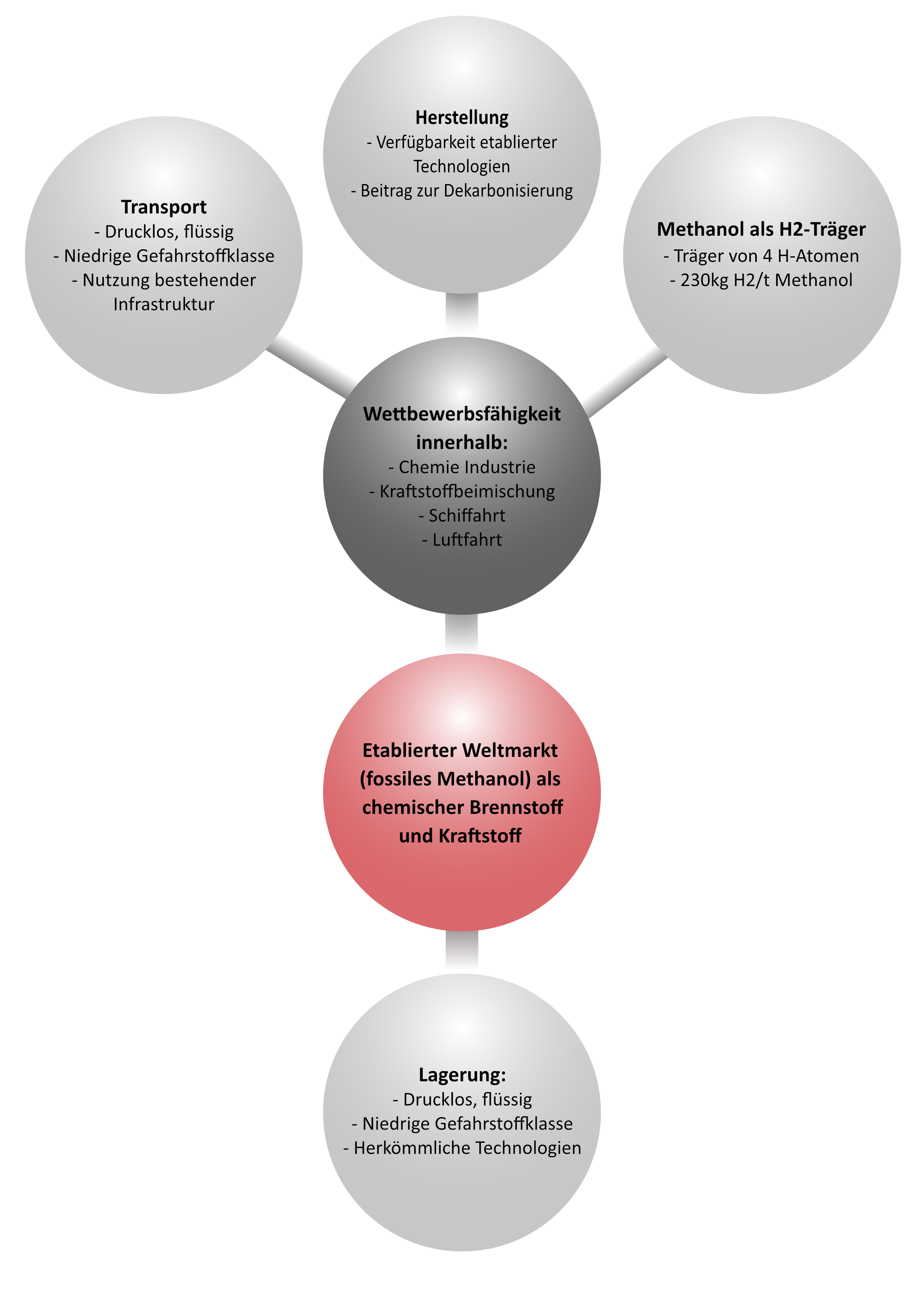

Why methanol?

Potentials for Tunisia

Economic: Positive effects for sustainable socio-economic development

Short / medium term

- Jobs during the construction period

- Creation of a permanent local supplier / service infrastructure

- Meeting local demand for H2 / methanol

- Connection to international markets through international export

Medium / long term

- Future expansion of capacity for H2-generation

- Establishment of new value chains (O2 andCO2)

- Establishment of a local processing industry for H2 / methanol (derivatives)

- Development of technological and production competence in a modern industry

The process steps

THE CSP-PV-HYBRID Power Plant

A hybrid system consisting of a concentrated solar power (CSP) system with salt storage and a photovoltaic system provides continuous power generation at the project site.

CO2 Separation

The amine scrubbing process enablesCO2 capture from the exhaust gas of unavoidableCO2 sources.

Electrolysis

In high-pressure alkali electrolysis, demineralized water is split into hydrogen and oxygen.

MEthanol process (synthesis and distillation)

The recovered hydrogen and capturedCO2 are synthesized to crude methanol in methanol synthesis and then distilled to 99.85% pure methanol in methanol distillation.

The process steps

THE CSP-PV-HYBRID Power Plant

A hybrid system consisting of a concentrated solar power (CSP) system with salt storage and a photovoltaic system provides continuous power generation at the project site.

Co2 Separation

The amine scrubbing process enablesCO2 capture from the exhaust gas of unavoidableCO2 sources.

Electrolysis

In high-pressure alkali electrolysis, demineralized water is split into hydrogen and oxygen.

MEthanol process (synthesis and distillation)

The recovered hydrogen and capturedCO2 are synthesized to crude methanol in methanol synthesis and then distilled to 99.85% pure methanol in methanol distillation.